Powder blending is crucial for many reasons. In the food industry, powders need to be blended to form the right ingredients or to provide the correct flavor. In the agriculture field, blending is required to mix the appropriate nutrients for fertilizers. Blending is also extremely important in the pharmaceutical industry, as it helps to create medications to treat various conditions. Additionally, powders are blended for the purpose of coating certain products or materials, for the purpose of improving product quality or to alter current properties of materials, among others.

Powder blending is nothing new or revolutionary. In fact, it’s among the oldest unit operations in solids handling. What is new, however, is the technology and equipment that continues to evolve for powder blending purposes as designers and engineers better understand what types of powders need to be blended and address challenges or equipment shortcomings accordingly.

The Various Types of Blending

As you may imagine, there are several different types of blending, which all boils down to what types of powders need blending and what the end application is. There are three basic types of blenders. These are classified as small-scale random motion (also commonly referred to as “diffusion”), large-scale random motion (also commonly referred to as “convection”) and shear.

As the name implies, diffusion blending works with smaller particles and occurs when said powders are distributed over a fresh interface. Diffusion blending is important when high homogeneity is desired. It’s also a rather slow blending style. Conversely, convection blending works with large particles and uses an impeller or similar instrument to move particles from one point to another. Convection blending is ideal for cohesive materials, and this type of blending also enables liquids to be added during the process. Finally, there’s the shear style of blending, which incorporates additional materials, such as granules, to help the blended mix reach a certain level of consistency.

Now that we’ve briefly gone over the different types of blending, it’s worth pointing out some of the more popular solid-solid blending equipment. The three most popular are ribbon blenders, tumble blenders and vertical blenders. In this piece, however, we’ll focus more on what is involved in tumble blending and ribbon blending.

Tumble vs. Ribbon Blending

Tumble blending and ribbon blending are two of the most popular types of blending for solid-solid mixing purposes. Ribbon blenders, specifically, are a good example of high-speed convective blending in that they’re able to move large particles from one point to the other and in a very fast manner. Ribbon blenders typically consist of a U-shaped trough and an agitating device that consists of several ribbons, which thereby work to move material in various directions. These ribbons are fast operating, with the potential of reaching 300 feet per minute, or fpm. These ribbons move powder in both radial and lateral directions. Ribbon blenders are available in both vertical and horizontal configurations.

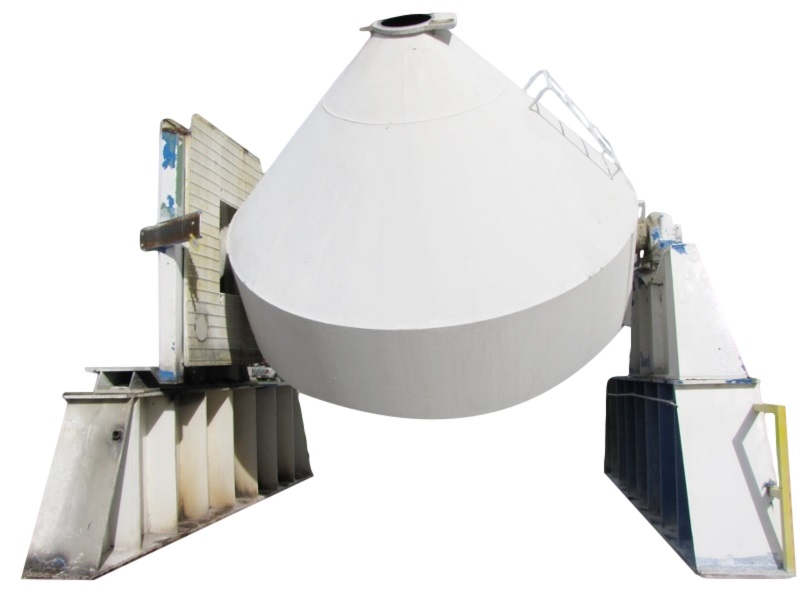

Tumble blending, on the other hand, is best for materials that require low impact. Specifically, tumble blenders are rotating mixers that are often available in several configurations, two of the most notable being double cone and V-shaped. Often times, these configurations are also interchangeable.

Tumble blenders operate somewhat slowly, usually at speeds of anywhere from 5 to 25 rpm, or revolutions per minute. They work via the diffusion style, which, as we covered earlier in this piece, blends smaller particles.

But how do you know which one is right for you if speed of powder blending isn’t a huge issue and the blend you’re dealing with would suffice in either application? Here’s a look at some further considerations to help you make the choice between tumble blending and ribbon blending.

- Tumble blenders are generally larger than ribbon blenders, especially vertical ribbon blenders, which take up the least amount of room on a plant floor. So if space is at a premium in your shop, know that a vertical ribbon blender will likely be the best option. Generally speaking, tumble blenders are the types of mixers that take up the greatest amount of space.

- Do you need the blender to discharge completely? If that’s the case, then the tumble blender is your best bet, as such mixers discharge near 100 percent.

- When it comes to producing the highest-quality, lump-free blend, ribbon blenders are the ideal mixer. That’s because the high speeds at which the ribbon blender works at ensures that the product it is processing mixes efficiently. While you can purchase and install lump breakers or the likes of choppers on any type of blender, ribbon blenders are still a cut above the rest when it comes to producing lump-free.

- Heat or no heat? Ribbon blenders generate more heat than other types of blenders, so this should be a consideration when selecting a blender. However, it’s really only a problem for heat-sensitive applications, as the increase in heat is not significant.

- Capacity: Ribbon blenders usually only work effectively with powder batches that take up at least half of its capacity, which can be an issue if smaller quantities of product need to be processed. Tumble blenders, on the other hand, usually work just as well when they’re at 10 percent capacity as they do when they’re at 100 percent capacity.

- Cost: Cost is always a big consideration behind the purchase of new equipment. When it comes to the cost of blenders, they can range from several thousand dollars to tens of thousands of dollars, certainly no small drop in the bucket for companies. Ribbon blenders, however, are considered the most affordable blender compared to other mixing equipment. Now’s also a good time to mention that if you need a blender, you don’t necessarily have to buy brand new. You can buy a previously owned blender, which you can find on a site such as Bid on Equipment and receive a like-new piece of equipment at a used price – no matter whether it’s a ribbon blender or tumble blender.

Though we’ve mentioned many differences between tumble blenders and ribbon blenders, it’s worth mentioning one significant commonality – and that’s blending accuracy. Specifically, both are very good at doing their jobs and creating a well-blended end product when they’re used under the appropriate circumstances. So while it’s important to note the differences between tumble and ribbon blenders, rest assured that each do their job very well when used with the right powders.

For more information on tumble blenders, ribbon blenders and all other types of blending systems – and to browse available equipment currently in stock – visit Bid on Equipment today.